Tel:0512-66958483

Email:engforlife-mkt@efl-tech.com

試劑/耗材

Reagents / Consumables

Hyaluronic Acid Methacryloyl (HAMA);EFL-HAMA-150K/400K

The kit includes hyaluronic acid methacryloyl and photoinitiator LAP.

All products in the HAMA range can be used in cell culture, biological 3D printing, tissue engineering, etc.

This product is for research use only and can not be used in humans.

Salesperson:Panpan Wang(EFL)

Phone:15335258233

Email:engforlife-mkt@efl-tech.com

Foreign distributor:ANR Technologies Pte Ltd

Hyaluronic acid (HA) is a natural glycosaminoglycan polymer consisting of D-glucuronic acid and N-Acetyl-D-Glucosamine as disaccharide structural units. It is a component of the extracellular matrix of animal tissues and has good moisture retention properties. Its content is high in brain tissue, synovial fluid, and vitreous body. HA plays an important role in many biological processes such as cell proliferation, differentiation, morphogenesis, inflammation, and wound healing.

Hyaluronic acid methacryloyl (HAMA) can be photo-crosslinked by grafting methacrylate group on the molecular chain of hyaluronic acid. Due to its easy shaping capability and good biocompatibility, HAMA-based material systems have been applied in many biomedical research fields, including: chondrocyte culture and cartilage regeneration and repair, tumor model construction, high-strength and adhesive hydrogel construction, drug controlled release, microneedle preparation, wound dressing, biosensor, postoperative anti-adhesion, etc. In addition, a large number of carboxyl and hydroxyl groups on HA molecules also provide abundant reactive sites for chemical modification, making it an excellent platform material, such as the introduction of adhesion groups, drug/active factor grafting, etc.

The HAMA product from EFL team (EFL-HAMA series) has stable physicochemical properties through strict raw material screening and quality testing. It can be cured within 10 seconds with visible light irradiation, has good biocompatibility, strong material scalability, and can provide a variety of viscoelastic properties to adapt to different applications. HAMA can be combined with GelMA from EFL to better simulate the microenvironment of cartilage, brain and other body tissues, obtain better cell 3D culture and bio-ink.

Cell culture, biological 3D printing, tissue engineering, etc.

Dry kit: room temperature, 3 months; 4℃, 12 months; -20℃, 18 months.

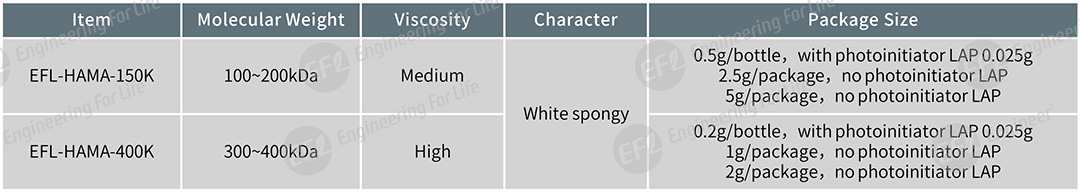

Fig 1. Synthesis reaction mechanism and NMR spectrum of HAMA

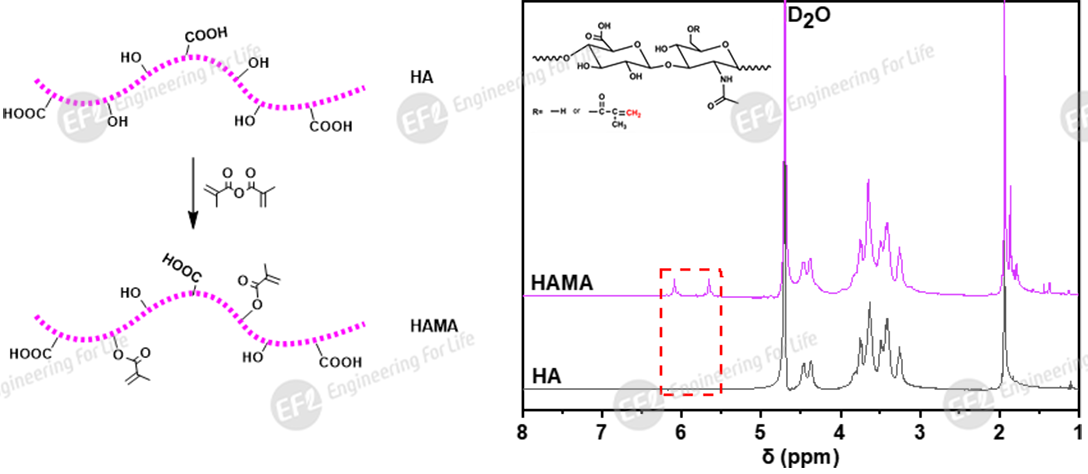

Fig 2. Rheological properties of HAMA-150K at different concentrations: (A) photocrosslinking process; (B) storage modulus G’ after curing; (C, D) viscosity

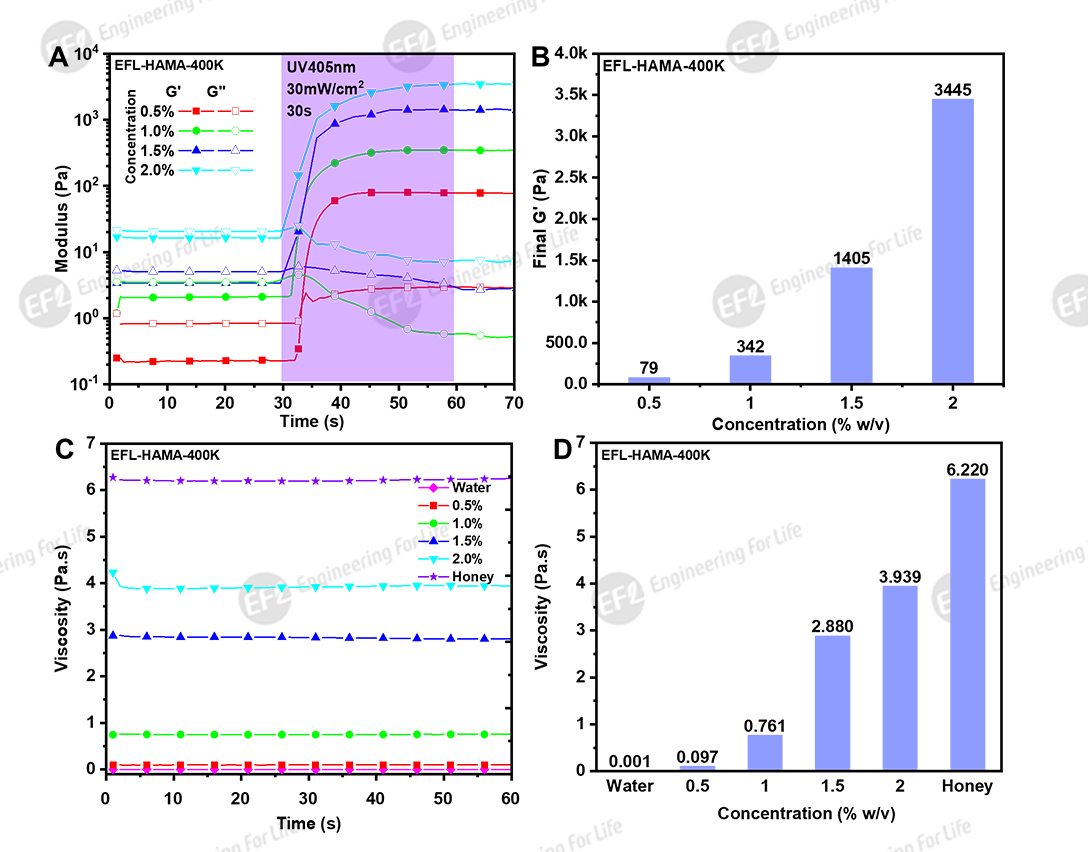

Fig 3.Rheological properties of HAMA-400K at different concentrations: (A) photocrosslinking process; (B) storage modulus G’ after curing; (C, D) viscosity

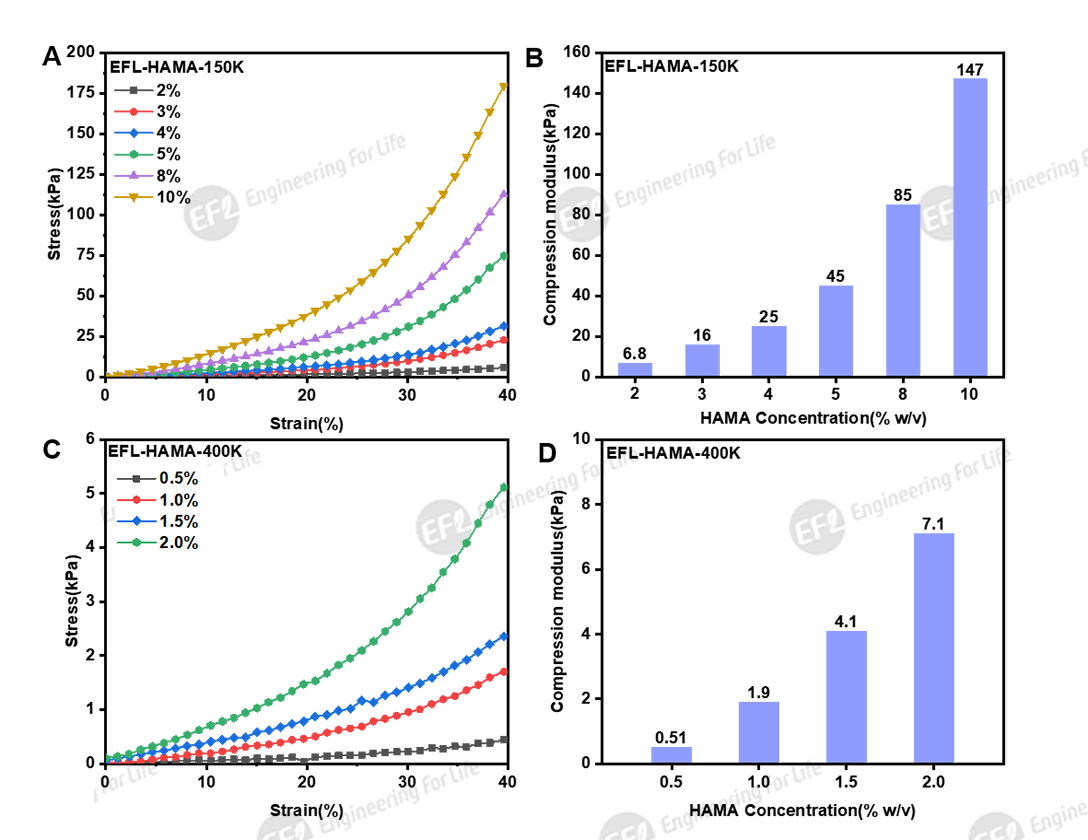

Fig 4. Compressive properties of HAMA at different concentrations (405nm light source, 30mW/cm2, 30s): (A, C) stress-strain curve; (B, D)compression modulus

Fig 5. HAMA hydrogel 3D cell culture

EFL-HAMA hydrogels cure quickly and have adjustable mechanical properties, which show excellent molding results in projective light curing 3D printing (DLP) applications. The BP-8600 photocurable bio-3D printer from EFL team can easily realize the complex structure manufacturing of HAMA.

Fig 6. HAMA structure printed by photocuring bio-3D printer (EFL-BP-8601 Pro)